BAUX Pulp Panels

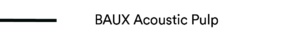

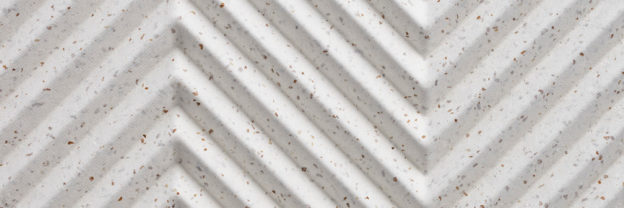

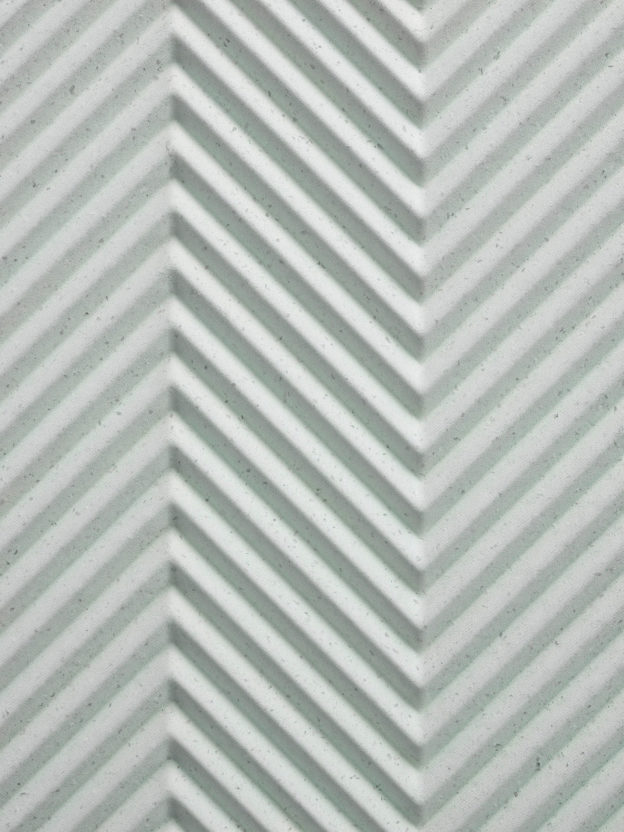

The 100% bio-based BAUX Acoustic Pulp panel is the first in the world to uncompromisingly combine the performance properties of sound absorption, safety and durability with sustainability and modern aesthetics. The patterns of BAUX Acoustic Pulp Panels are inspired by folding paper, and are available in 3 patterns; Origami Pulse, Origami Energy and Origami Sense.

* All panels can be mixed and matched together. Observe that the patterns do not fully sync/align if put vertically next to each other

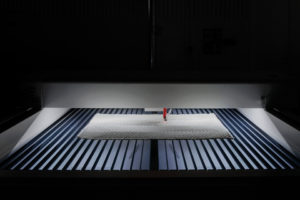

Acoustic Pulp panels are now stocked and available for immediate delivery. The production process has been automated and robotised, resulting in faster, better, and more efficient panel production. To place an order, please get in touch with your local representatives or email [email protected].

Patterns inspired by folding paper

We started by folding paper. For weeks, we played with a multitude of different origami and architecture-inspired lines and shapes until we discovered a series of simple patterns that both matched our aesthetic and provided acoustical benefits.

BAUX Acoustic Pulp drastically pushes the boundaries of cellulosic properties to a completely new level

100%

Bio-based

100%

Recyclable

100%

Biodegradable

0%

Pollution or waste

Biomimicry engineered

Lightweight

Durable

Fire retardant

Water repellent

Colour made from wheat

Laser enhanced sound absorption

Excellent sound absorption

Pulp material and colours

Pulp Natural Wheat

Wheat 05%

Colour - derived from wheat.

The Acoustic Pulp panel – Natural Wheat is achieved using 5% wheat bran. With the three origami patterns, you can combine endless possibilities for harmonising with different space designs.

Pulp Bio Colours

Bio Blue Chalk

Bio Green Soil

Bio Red Mud

Bio Yellow Terra

Bio Rose Clay

Biodegradable colours.

A palette comprising subdued, biodegradable colours provides the opportunity to enhance acoustics while also honouring principles of sustainable design. The bio-based colours seamlessly blend functionality, aesthetics, and environmental responsibility.

BAUX Acoustic Pulp Toolkit

If you want all the files and instructions gathered in one package – look no further! This toolkit contains all the BAUX Acoustic Pulp files you will need.

- Catalogue – (.pdf)

- Brochure – (.pdf)

- Installation manual – (.pdf)

- BIM / Revit – (.zip)

- CAD / 3d – (.zip)

- Mounting DWG – (.dwg)

- AI Files – (.ai)

Brochures & catalogues

Brochure

Catalogue

The larger catalogue is web optimised for desktop viewing and the size allows the catalogue to be forwarded. The catalogue is made as a magazine and contains the story of BAUX Acoustic Pulp, Into the wild along with measurements.

Installation manual

See mounting and installation instructions for BAUX Acoustic Pulp Panels.

3D files - Acoustic Pulp

3D/CAD

For many working professionals, 3d and CAD modelling is an essential tool for visualising design for upcoming projects. Download all Acoustic Pulp files that work with AutoCAD, Sketchup, ArchiCAD, Rhino among others.

- .3ds

- .dwg

- .dxf

- .igs

- .skp

- .sldprt

- .step

Adobe files - Acoustic Pulp

Adobe Illustrator

All our acoustic Pulp products are featured as Adobe Illustrator files. An easy and efficient tool to make designs.

- .ai

Adobe Photoshop

All our acoustic Pulp products are featured as vectorized photoshop files. An easy and efficient tool to make designs.

- .psd

Other

Material Data Sheet

In the material data specification sheet (MSDS) you can find all essential information about the BAUX Acoustic Pulp in a compressed way. See the measurements, material specifications, installation and general information about the acoustic Pulp in this material data sheet.

Request Samples

If you are interested in getting colour samples for your upcoming project, let us know!

Certificates & Technical Documents

Sustainability is a fundamental part of our core business model. Designing the sustainable acoustic building materials for tomorrow means producing environmentally friendly materials today. Find out more on our sustainability and certificate site.

Designed by

Form Us With Love

Form Us With Love is an international design studio founded in 2005. At the studio’s core lies a process that blends traditional creative practices with a lean, strategic application. The central intention is to evolve with the needs of each project, its place in the market, and the ever-changing needs of real people.

We design for an important reason: to improve life overall.

That idea on its own is vast and difficult to tackle; progress is a constant game of one step forwards and two steps back. People have different needs than a business has, though much of it overlaps. And what is a solution for the planet now has to be taken into the context of the centuries it might be around.

We consider a lot of elements when designing a product — sustainability being chief among them. Each solution we find gets added to our broader knowledge, so we’re not starting from zero when we arrive at a brand new problem.

We aim to design real change by understanding industry and culture, systemic change that has implications across life’s various sectors. To do this, we identify industrial opportunities that can solve social needs and design solutions with a balanced use of resources. This results in necessary, high-quality products that deliver business growth and create real change.